Introduction

Programmable Logic Controllers (PLCs) are at the core of today’s industrial automation systems. They play a critical role in keeping machinery and processes running optimally.

Programmable logic controller (PLC) instrumentation engineers often face challenges in troubleshooting and keeping these critical components in good working order.

In this blog, we’re going to look at some of the most advanced troubleshooting techniques for PLCs that are specifically designed for Automation and instrumentation engineers. This will give them the tools and expertise they need to solve even the most complex problems.

Understanding PLC Troubleshooting Basics for automation engineer

Before diving into advanced techniques, it’s essential to have a solid foundation in PLC troubleshooting basics. Instrumentation engineers should be well-versed in:

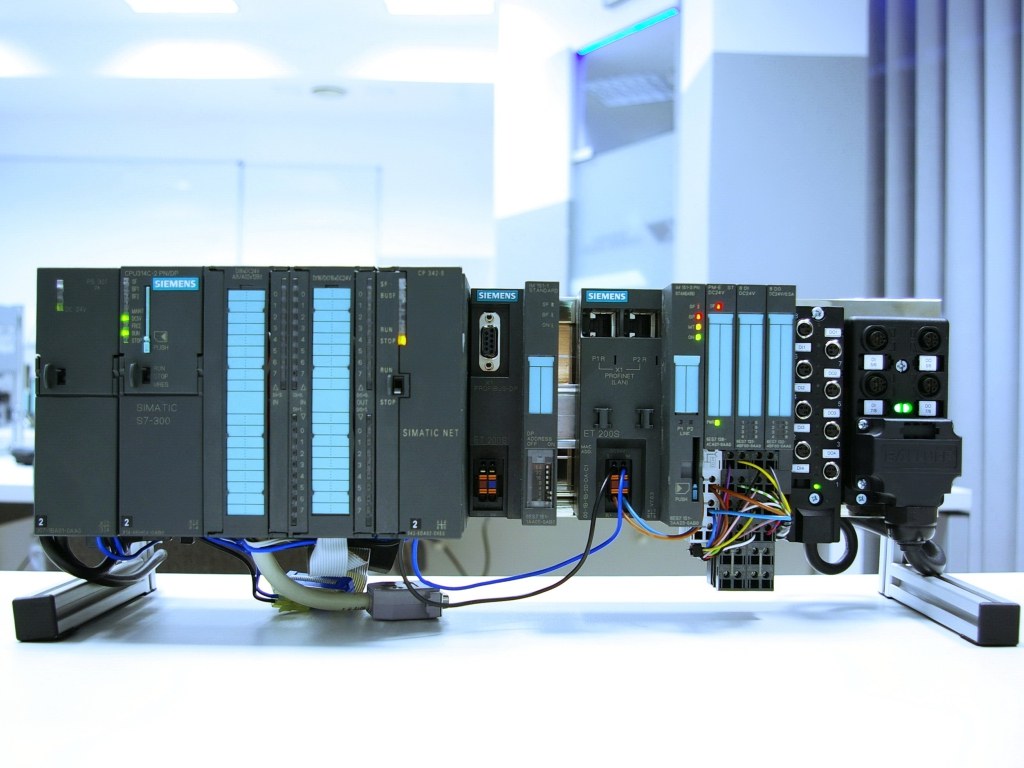

1. **Understanding PLC Architecture**: Familiarize yourself with the different components of a PLC, including the CPU, I/O modules, and communication interfaces.

2. **Reading PLC Documentation**: Make sure to thoroughly study the PLC’s user manual, ladder logic diagrams, and wiring diagrams. This information is invaluable when troubleshooting.

3. **Identifying Error Codes**: Learn to interpret error codes and diagnostic messages provided by the PLC software. These codes often hold clues to the root cause of issues.

Advanced PLC Troubleshooting Techniques

### Technique 1: Analyzing PLC Memory

1. **Memory Integrity Checks**: Perform regular checks on PLC memory integrity. Look for memory leaks, corruption, or unusual spikes in memory usage, as these can lead to erratic behavior.

2. **Memory Backup and Restoration**: Familiarize yourself with the process of backing up and restoring PLC memory. Being able to quickly recover from memory-related issues is crucial.

### Technique 2: Network Diagnostics

1. Ethernet Troubleshooting**: Understand Ethernet communication protocols and tools like Wireshark to diagnose network-related PLC problems.

2. Device Configuration Checks**: Ensure proper IP address assignments and subnet configurations for all devices in your network. Misconfigurations can disrupt communication.

I/O Module Testing

1. **Input and Output Verification**: Periodically test and verify the functionality of input and output modules. Use a multimeter or oscilloscope for precise measurements.

2. **Hot Swapping**: Learn how to hot-swap malfunctioning I/O modules without interrupting the overall PLC operation. This can minimize downtime.

### Technique 4: Advanced Programming Debugging

1. **Online Monitoring**: Use online monitoring tools provided by your PLC software to observe ladder logic execution in real-time. This is invaluable for identifying logic errors.

2. **Force and Unforce Tags**: Understand how to force and unforce tags in your PLC program to simulate conditions and test logic without affecting the actual process.

### Technique 5: Alarm and Event Analysis

1. **Alarm Log Review**: Regularly review the alarm and event logs to identify recurring issues or patterns that may point to underlying problems.

2. **Trend Analysis**: Implement trend analysis tools to track variables over time. Sudden spikes or drops can indicate problems that may not be immediately apparent.

Advanced Troubleshooting Tools

### Technique 1: PLC Diagnostic Software

1. **Use of Diagnostic Software**: Explore third-party diagnostic software tools that can provide in-depth insights into your PLC’s operation and health.

2. **PLC Emulators**: Consider using PLC emulators for offline troubleshooting and testing, allowing you to replicate issues without affecting the production environment.

### Technique 2: Remote Access and Monitoring

1. **Remote Access Solutions**: Implement secure remote access solutions that enable you to troubleshoot PLCs from anywhere, reducing the need for on-site visits.

2. **Real-time Data Visualization**: Utilize real-time data visualization tools to monitor PLC performance remotely and identify anomalies as they occur.

## Section 4: Collaborative Troubleshooting

1. **Cross-Functional Teams**: Establish cross-functional teams that include not only engineers but also technicians, electricians, and operators. Different perspectives can lead to faster issue resolution.

2. **Documentation Sharing**: Encourage thorough documentation of PLC configurations and changes. Sharing this information among team members can expedite troubleshooting.

## Section 5: Continuous Learning and Training

1. **Stay Updated**: PLC technology is constantly evolving. Stay updated with the latest advancements by attending training sessions, webinars, and conferences.

2. **Hands-On Practice**: Practice is key to becoming proficient in PLC troubleshooting. Set up a lab environment to experiment with different scenarios and techniques.

Conclusion

Instrumentation engineers play a pivotal role in maintaining and troubleshooting PLCs in industrial settings. By mastering these advanced PLC troubleshooting techniques and continuously expanding their knowledge, they can ensure that automation systems run smoothly and efficiently. Remember that PLC troubleshooting is both an art and a science, and with the right tools and expertise, even the most complex issues can be resolved effectively.

Home Page Our Face Book Page Our You Tube Channel