In this blog, we are going to post 15+ PLC Interview Questions and answers.

Q 1: What is the meaning of PLC?

Ans: PLC means “Programmable Logic Controller”. PLC is a digital computer-based system used to automate industrial processes.

Q 2: What is PLC and in which field is it used?

Ans: PLC is an industrial controller, which is used in industrial automation.

With this machines and processes can be controlled.

Q 3: What is Ladder logic and what is its purpose in PLC?

Ans: Ladder logic is a graphical programming language, which is used to write programs in PLC. This allows logic and conditions to be easily defined.

Q 4: What are the inputs and outputs of PLC?

Ans: The inputs of PLC are sensors or switches which measure physical parameters like temperature, pressure, and position. Actuators or solenoids are used to control outputs, machine or process.

Q 5 : What is “Control Panel” in PLC?

Ans: “Control Panel” in PLC is the cabinet containing the components of PLC like CPU, power supply, I/O modules, and communication devices.

Q 6: What is Scan Cycle in PLC?

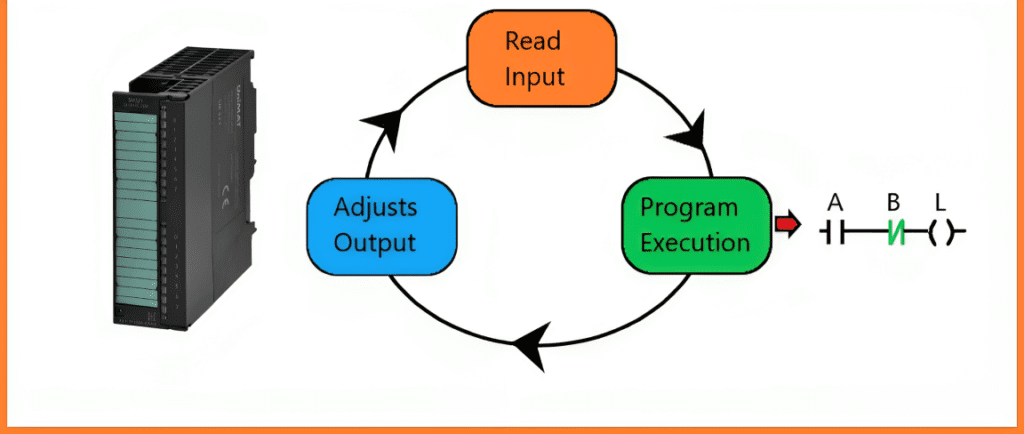

Ans: The scan cycle of PLC defines the process in which PLC reads all the inputs and checks their state, Evaluates the logic, and Then updates the outputs.

Q 7: What is the difference between PLC and DCS?

Ans : Both PLC and DCS are used for industrial automation.

But in PLC the sequence of tasks is set with the help of logic and programming.

A DCS consists of several separate units or “nodes” that are connected within a larger network. Every node controls and monitors its own area. This system has become more decentralized.

Q 8: What are the programming languages used in PLC programming?

Ans: Common programming languages of PLC are ladder logic, Function block diagrams (FBD), and Structured text (ST).

But, the commonly used programming language is Ladder Logic. This can be easily done using relay logic.

Q 9: In which areas PLC is used?

Ans: PLC is used in manufacturing plants, power plants, chemical plants, and other industrial processes where automation and control is required.

Q 10 : What is the role of power supply for PLC?

Ans: The power supply for PLC provides the required voltage and current for its operation. This power supply is very important for the PLC to function properly.

Q 11: What is the difference between PLC and PID controller?

Ans: PLC is an electronic device which is used in industrial automation. Its main objective is to control and automate industrial processes and machinery.

PID (Proportional-Integral-Derivative) controller is a type of feedback control system that controls process variables. With this parameters like temperature and pressure can be regulated.

Q 12 : What is “Scan Cycle Time” in PLC?

Ans: “Scan Cycle Time” of PLC is the time taken to read PLC inputs, evaluate logic, and update outputs.

Q 13: What is “Coil” in PLC programming?

Ans: “Coil” in PLC programming is an output instruction that controls output devices, such as motors, solenoids, and lamps.

Q 14: What is “Contact” in PLC programming?

Ans: In PLC programming “Contact” is an input instruction which is connected to input devices and relay states and helps in evaluating the logic.

Q 15 : What are “Timers” and “Counters” in PLC?

Ans: “Timers” in PLC generate specific time delay by counting time, whereas “Counters” count input pulses to reach a specific count.

Q 16: What are “Rising Edge” and “Falling Edge” in PLC programming?

Ans: “Rising Edge” in PLC programming when the input signal changes from OFF (Low) state to ON (High) state.

“Falling Edge”

When the input signal changes from ON (High) state to OFF (Low) state.