Namaskar dosto! Iss blog post mein, aaj hum aapko ek bohot mahatvapurna vishay par baat karne ja rahe hain – PLC analog input aur output configuration. PLC yaani Programmable Logic Controller ek electronic device hai jo humare industrial automation systems ko control karne mein madad karta hai. Is blog post mein, hum aapko analog input aur output configuration ke bare mein jaankari denge. Toh chaliye shuru karte hain!

PLC Analog Input and Output (PLC Signals) : Ek Samanya Parichay

Sabse pehle, humein samajhna hoga ki analog input aur output kya hote hain. Digital input aur output toh aapne suna hi hoga – jaise ki ek switch ka on/off state ya ek LED ka on/off state. Lekin analog input aur output thoda alag hai.

Analog input mein, hum ek continuous range of values ko monitor karte hain. Jaise ki temperature sensor jo har kuch der mein alag temperature ko measure karta hai. Iska matlab hai ki analog input ke signals ek specific value ke bajay ek range mein aate hain.

Analog output mein, hum bhi ek range mein values ko generate karte hain. Jaise ki ek motor ko speed control karna. Yahan, PLC analog output signals ko generate karta hai jo motor ki speed ko vary karne mein madad karte hain.

PLC Analog Input Configuration

Ab jab humne samjha ki analog input aur output kya hote hain, toh chaliye dekhte hain ki PLC analog input configuration kaise hoti hai.

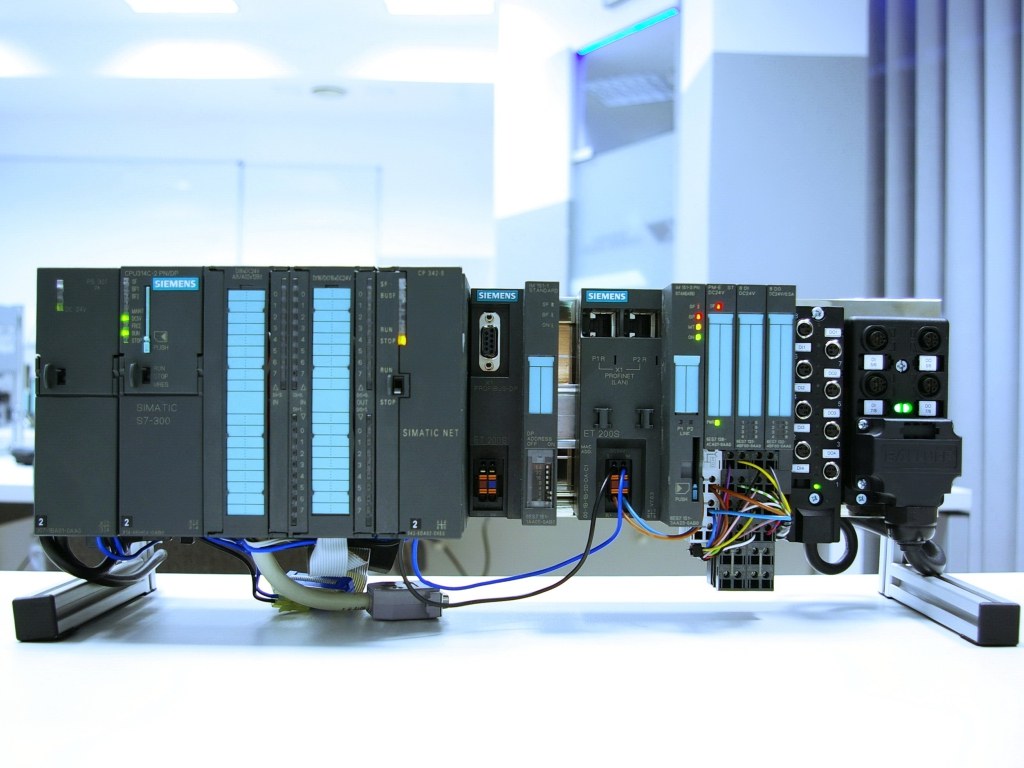

- Analog Sensors Connect Karein: Sabse pehle, aapko apne analog sensors ko PLC se connect karna hoga. Yeh sensors voltage ya current ke form mein analog signals generate karte hain. PLC mein usually analog input cards hote hain jinhe aap in sensors se connect kar sakte hain.

- Scaling Parameter Set Karein: Har sensor ki measurement range alag hoti hai. Toh aapko PLC mein scaling parameters set karne honge taaki PLC sahi tarah se analog signals ko interpret kar sake. Scaling parameters mein minimum aur maximum values ko define kiya jata hai, jisse PLC input values ko sahi tarah se interpret kar sake.

- Signal Conditioning: Kuch sensors ki output signals noisy hoti hain, isliye aapko signal conditioning ka bhi khayal rakhna hoga. Signal conditioning se signal noise ko kam kiya jata hai taaki PLC sahi measurement kar sake.

- Data Logging: Agar aap data logging karna chahte hain, toh aapko analog input values ko store karne ke liye PLC mein memory allocate karna hoga. Isse aap baad mein data analysis kar sakte hain.

- Control Algorithms: Analog input values ka use control algorithms mein bhi kiya jata hai. Jaise ki temperature control system mein, aap analog input values ka use temperature ko maintain karne ke liye kar sakte hain.

PLC Analog Output Configuration

Ab aate hain PLC analog output configuration par.

- Output Modules Connect Karein: PLC mein analog output signals generate karne ke liye aapko analog output modules ka use karna hoga. Yeh modules output signals ko voltage ya current form mein generate karte hain.

- Scaling Parameter Set Karein: Analog output configuration mein bhi scaling parameters set karne hote hain taaki PLC sahi tarah se analog signals generate kar sake. Scaling parameters mein minimum aur maximum values ko define kiya jata hai.

- Control Logic Define Karein: Analog output signals ko generate karne ke liye aapko control logic define karna hoga. Isme aap decide karte hain ki kis tarah ke changes chahiye output signals mein based on input values.

- Safety Considerations: Analog output configuration mein safety ka bhi khayal rakhna bohot zaroori hai. Agar aap kisi critical process ko control kar rahe hain, toh safety features ko incorporate karna hoga taki kisi bhi unwanted situation se bacha ja sake.

PLC Analog Configuration Ka Prayog

Ab jab humne PLC analog input aur output configuration ke basics samjhe hain, toh aap soch rahe honge ki PLC analog configuration ka prayog kaise hota hai.

PLC analog configuration ka use manufacturing units, chemical plants, aur dusre industries mein hota hai jahan par continuous monitoring aur control ki avashyakta hoti hai. Aise industries mein, analog sensors aur output devices ka prayog bohot common hota hai.

- Temperature Control: Ek common example hai temperature control. Manufacturing units mein temperature ko maintain karna bohot mahatvapurna hota hai. Iske liye analog temperature sensors ka use hota hai jo PLC ke analog input ports se connect hote hain. PLC fir analog output ports se cooling systems aur heaters ko control karta hai.

- Pressure Monitoring: Chemical plants mein pressure monitoring ke liye bhi PLC analog input configuration ka use hota hai. Pressure sensors analog input ports se connect hote hain aur PLC un signals ko interpret karke safety measures aur control actions le leta hai.

- Motor Speed Control: PLC analog output configuration ka use motor speed control ke liye hota hai. Manufacturing units mein motors ki speed ko vary karne ke liye PLC analog output signals generate karta hai.

- Liquid Level Control: Liquid level monitoring aur control bhi madhyam star par PLC analog configuration ka ek prime example hai. Aise plants mein jo liquids ka use hota hai, wahan par liquid level ko monitor aur control karna bohot mahatvapurna hota hai.

- Quality Control: Industries mein product quality ko maintain karne ke liye bhi PLC analog input configuration ka use hota hai. Sensors product ke parameters ko measure karte hain aur PLC un measurements ke basis par control actions leta hai.

Conclusion

Toh dosto, is blog post mein humne dekha ki PLC analog input aur output configuration kaise hoti hai aur kis tarah se iska industrial applications mein upayog hota hai.

PLC analog configuration ka knowledge bohot mahatvapurna hai agar aap industrial automation field mein kaam kar rahe hain ya is field mein career banana chahte hain.

PLC technology continuously evolve hoti ja rahi hai, aur isme aane wale samay mein aur bhi naye tarike aur features aane ki sambhavna hai. Isliye, aapko up-to-date rehna aur latest trends aur technologies ko follow karna hoga.

Hum ummid karte hain ki yeh blog post aapke liye informative raha hoga. Aapko yeh post kaisi lagi reply kijiye.

Our Face book Page Our You Tube Channel Home Page