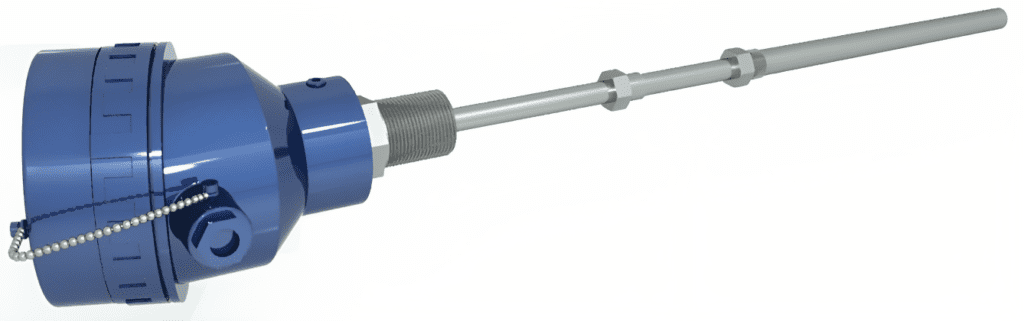

Thermocouple temperature sensors are sensors that measure the temperature of the environment. They are commonly used in industrial processes, scientific experiments, and everyday applications. In Instrumentation, they are mainly used for industrial processes. They also help in temperature regulation. Thermocouple sensors are one of the most widely used and versatile temperature sensors because they are reliable, easy to use, and come in a wide range of temperatures. In this blog post, we will discuss and explore the principles behind thermocouples, their applications across various industries, and the advantages they offer over other temperature sensing technologies.

Working Principles of Thermocouple sensor/ Temperature sensor

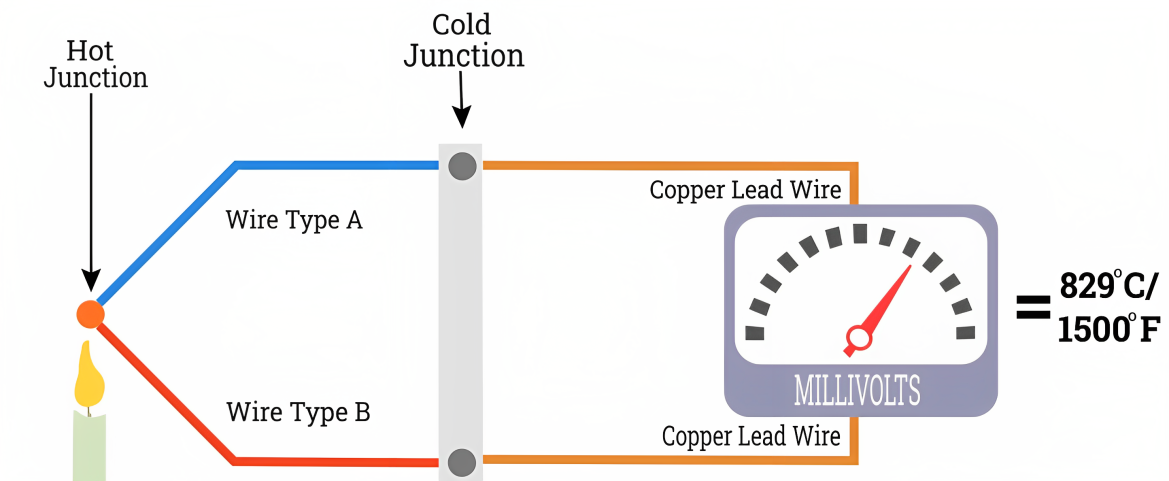

Thermocouple is a type of temperature sensor that uses the Seebeck effect. Basically, it works by creating an EMF or voltage between two different metals when they’re exposed to a temperature change.

The junction where the two metals meet is referred to as the “hot junction,” while the other ends of the metals are termed the “cold junctions” or “reference junctions.” The voltage generated at the hot junction is directly proportional to the temperature difference between the hot and cold junctions.

Metal alloys are used in a variety of ways to form different types of thermocouple, each with its specific temperature range and characteristics. Common thermocouple types include Type K (chromel-alumel), Type J (iron-constantan), Type T (copper-constantan), Type E (chromel-constantan), and more. The choice of thermocouple type depends on the required temperature range, accuracy, and environmental conditions of the application.

Applications of Thermocouples

Thermocouples find applications across a wide range of industries due to their versatility, ruggedness, and ability to measure high temperatures. Some notable applications include:

1. **Industrial Processes**: These sensors are extensively used in manufacturing industries to monitor temperature in processes such as metal refining, glass production, and plastic molding. They are capable of withstanding high temperatures and harsh environments.

2. **Energy Production**: These sensors play a critical role in energy production, from monitoring temperature in power plants to ensuring the efficiency and safety of nuclear reactors.

3. **Aerospace and Automotive**: In aerospace and automotive engineering, These sensors are used to monitor engine temperature, exhaust gases, and other critical components to ensure optimal performance and prevent overheating.

4. **Food Industry**: These sensors are employed in ovens, refrigerators, and food storage units to maintain consistent temperatures and ensure food safety.

5. **Medical Applications**: These sensors are used in medical devices like patient monitors, incubators, and laboratory equipment where precise temperature monitoring is essential.

6. **Research and Laboratories**: In scientific research, these sensors are commonly used for experiments that involve extreme temperatures, such as material testing, chemical reactions, and studies of phase transitions.

Advantages of Thermocouples

1. **Wide Temperature Range**: These sensors can measure temperatures from extremely low (cryogenic) to extremely high (over 2000°C) ranges. This wide operating range makes them suitable for various applications.

2. **Fast Response Time**: These sensors offer a quick response to temperature changes, making them ideal for applications where real-time monitoring and control are crucial.

3. **Ruggedness and Durability**: These sensors are designed to withstand harsh environments, including high vibration, moisture, and corrosive gases, making them suitable for industrial and outdoor applications.

4. **Simple Design**: These sensors have a simple construction consisting of just two wires. This simplicity contributes to their reliability and ease of use.

5. **Cost-Effectiveness**: Compared to some other temperature sensors, These sensors are relatively inexpensive to manufacture and replace, making them a cost-effective choice for various applications.

6. **Self-Powered Operation**: These sensors generate a voltage directly proportional to the temperature difference, eliminating the need for an external power source for measurement.

7. **Compatibility**: These sensors can be interfaced with a wide range of measuring instruments, controllers, and data acquisition systems.

Challenges and Considerations

While thermocouples offer numerous advantages, there are also some challenges and considerations to keep in mind:

1. **Accuracy**: The accuracy of These sensors can vary based on the type, temperature range, and environmental conditions. For applications requiring high precision, calibration and compensation techniques may be necessary.

2. **Cold Junction Compensation**: The accuracy of These sensors measurement depends on accurately measuring the reference temperature at the cold junction. This can be challenging, especially in dynamic or changing environments.

3. **Non-Linearity**: Thermocouple voltage-temperature relationship is not perfectly linear, especially over a wide temperature range. Linearization techniques or specialized electronics may be needed for high-precision measurements.

4. **Interference**: Electromagnetic interference and noise can affect the accuracy of thermocouple readings. Shielding and proper wiring practices can help mitigate this issue.

Conclusion

These sensors have stood the test of time as reliable and versatile tools for temperature measurement across various industries. Their principle of operation, wide temperature range, durability, and cost-effectiveness make them indispensable in applications ranging from industrial processes to scientific research. While challenges such as accuracy and compensation need to be addressed in certain scenarios, the benefits of thermocouples continue to make them a popular choice for temperature monitoring and control needs. As technology continues to advance, These sensors are likely to remain an essential component in the toolkit of temperature measurement and monitoring solutions.

Our You Tube Channel Our Facebook Page Home Page