Introduction:

Programmable Logic Controllers (PLCs) act as the foundation of contemporary industrial automation, enhancing efficiency and simplifying operations.

Whether you’re a budding engineer or someone looking to dive into the world of automation, understanding PLC programming is essential.

In this detailed tutorial, we’ll help beginners understand the fundamentals of PLC programming, establishing a strong base for excelling in this essential skill.

Understanding PLCs:

What is a PLC?

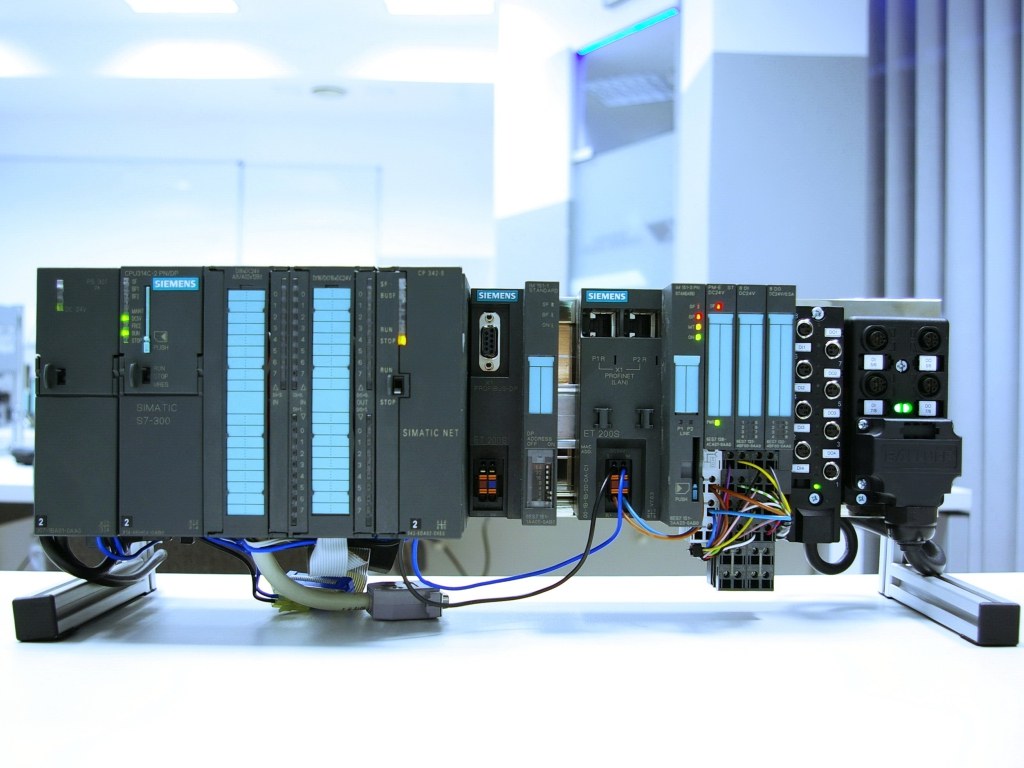

A Programmable Logic Controller (PLC) is a specialized industrial computer designed to control manufacturing processes and machinery. PLCs are programmable, meaning they can execute specific tasks based on the input they receive.

Why Use PLCs?

PLCs offer several advantages, such as robustness, reliability, and flexibility in controlling various processes. They are widely used in industries like manufacturing, energy, and even building automation.

Getting Started with PLC Programming:

1. Basic Components:

Before diving into programming, familiarize yourself with the fundamental components of a PLC system, including the CPU, input modules, output modules, and the programming device.

2. PLC Programming Languages:

Programmable Logic Controllers (PLCs) are designed to accommodate various programming languages, yet ladder logic stands out as the most common. Its design is reminiscent of electrical relay logic diagrams, which simplifies it for newcomers.

Additional languages are Structured Text, Function Block Diagrams, and Sequential Function Charts.

3. Choosing a PLC:

There are numerous PLC manufacturers, each offering a range of models. Siemens, Allen-Bradley, and Omron are popular choices. Choose a PLC that suits your application and budget.

Writing Your First PLC Program/PLC programming:

1. Setting Up the Programming Environment:

Use the manufacturer’s software to create a new project. Define the hardware configuration by adding input and output modules.

2. Understanding Basic Instructions:

Learn the basic PLC instructions such as input and output instructions, timers, counters, and comparison instructions. These form the building blocks of any PLC program.

3. Creating a Simple Program:

Start with a basic project, like turning on a motor when a sensor detects an object. Use ladder logic to design your program and assign addresses to inputs and outputs.

Advanced PLC Programming Concepts:

1. Timers and Counters:

Explore the use of timers and counters to control time-dependent and count-dependent processes. Understand different timer types such as on-delay and off-delay.

2. Data Handling:

Learn how to manipulate data using data handling instructions. This includes moving data between different memory locations, converting data types, and performing mathematical operations.

3. Analog Inputs and Outputs:

Understand how to work with analog signals. PLCs can handle not only digital but also analog inputs and outputs, enabling precise control of processes.

4. Structured Text Programming:

Delve into Structured Text, a high-level programming language that resembles traditional programming languages. It offers a more versatile and powerful approach for complex applications.

Troubleshooting and Debugging:

1. Monitoring and Simulation:

Use monitoring tools provided by the programming software to observe the status of inputs and outputs in real-time. Simulate the program to identify and fix potential issues before running it on the actual hardware.

2. Diagnosing Errors:

Learn to read and interpret error messages. PLCs often provide detailed diagnostic information to help troubleshoot problems efficiently.

Real-world Applications:

1. Case Studies:

Explore real-world applications where PLCs play a crucial role. Understand how PLCs are used in conveyor systems, robotic arms, and manufacturing lines.

2. Industry-specific Considerations:

Different industries have specific requirements. Learn about the unique challenges and solutions for industries such as automotive, food and beverage, and pharmaceuticals.

Staying Updated and Resources:

1. Online Communities:

Join online forums and communities to connect with other PLC programmers. Share experiences, ask questions, and stay updated on the latest trends and technologies.

2. Continuous Learning:

PLC technology is constantly evolving. Stay updated by reading industry publications, attending webinars, and exploring online courses.

Conclusion:

Becoming proficient in PLC programming is an enriching path that unlocks a universe of opportunities for automation. This guide acts as a foundation for newcomers, offering the necessary understanding and abilities to start a fulfilling career in industrial automation.

As you progress, feel free to delve into more complex subjects and expand the limits of what PLCs can accomplish in the constantly changing field of automation. Enjoy your programming journey!

Our You Tube Channel Home Page