Whether it’s hot or cold outside, or you are measuring parameters in industrial instrumentation, temperature plays a pivotal role. But do you know how temperature is precisely measured? This is where the importance of RTD Temperature Sensors comes into play. Today, we’ll dive into the world of RTD temperature sensors and how they can make your life easier. RTD, or Resistance Temperature Detector, is a device that accurately measures temperature by using electrical resistance. Let’s explore the fascinating realm of RTD temperature sensors!

RTD Temperature Sensors: An Overview

RTD temperature sensors are a type of temperature sensor that measures temperature through electrical resistance. These sensors are typically made from a platinum (Pt) wire that exhibits a change in electrical resistance with variations in temperature. They are commonly used for temperature monitoring, industrial processes, and scientific research. One key feature of RTD sensors is their linear output, meaning that their resistance changes linearly with temperature. This makes it easy to understand their output and accurately monitor temperature changes.

The Process of RTD Sensors in instrumentation

Understanding how RTD sensors work is crucial. In these sensors, a platinum wire is shaped in a specific way and an electrical current is passed through it. When the temperature changes, the resistance of the platinum wire also changes. By measuring this resistance change, the temperature reading is determined. Platinum is used because it is a highly stable and reliable metal that changes its resistance with temperature variations.

High Precision of RTD Sensors

One of the primary advantages of RTD sensors is their high precision. They provide a linear output, and their temperature range is broad. These sensors can detect even the smallest temperature differences.

Therefore, they find use in applications where temperature monitoring is critical. For example, they are used in medical equipment, manufacturing industry, process industry, aerospace, the automotive industry, and scientific research.

Due to their high precision, RTD sensors are employed in critical applications where precise temperature measurement is essential.

RTD Sensors vs. Thermocouples

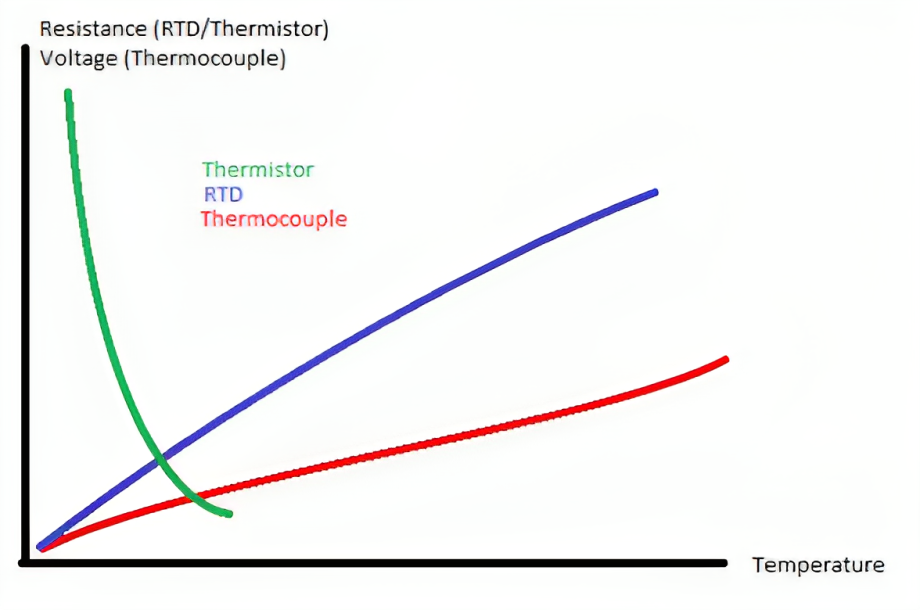

In comparison to RTD sensors, thermocouples are another common type of temperature sensor. Thermocouples consist of a junction between two different metals, which generates an Electromotive Force (EMF) in response to temperature changes.

This EMF is measured to determine temperature. However, when compared to RTD sensors, RTDs offer higher precision. Unlike thermocouples, RTD sensors provide a linear output, and their temperature range is wider.

Nevertheless, thermocouples are often used in high-temperature applications because of their heat-resistant construction. Therefore, your choice between the two sensors depends on your specific application.

Benefits of RTD Sensors

RTD sensors offer various benefits, making them a preferred choice for many applications:

- High Precision: RTD sensors provide precise temperature monitoring, allowing for reliable measurements in critical applications.

- Linear Output: These sensors offer a linear output, making it easy to understand and interpret temperature changes.

- Long-Term Stability: Thanks to the use of platinum, RTD sensors exhibit long-term stability, reducing the frequency of calibration.

- Wide Temperature Range: RTD sensors can be used in various applications due to their wide temperature range.

- Low Drift: Drift is minimal in RTD sensors, ensuring accurate and reliable readings.

- Low Self-Heating: RTD sensors generate minimal self-heating, resulting in accurate temperature measurements.

Applications of RTD Sensors

RTD sensors are used in a wide range of applications, and here are some prominent ones:

- Kitchen: RTD sensors are used for temperature monitoring in home kitchens, ensuring that your dishes are cooked at the right temperature.

- Industrial Processes: Industries employ RTD sensors for temperature monitoring in applications such as the chemical industry, pharmaceuticals, and food processing.

- Automotive: In the automotive industry, RTD sensors are used for engine temperature monitoring.

- Aerospace: RTD sensors play a critical role in aerospace applications where extreme temperature conditions are prevalent.

- Medical Equipment: Medical equipment, including blood bank freezers and incubators, use RTD sensors for precise temperature monitoring.

Conclusion

RTD temperature sensors are essential devices that aid in accurate temperature monitoring. Their high precision, linear output, and long-term stability set them apart from other temperature sensors. They find use in various settings, from home to industries and even aerospace.

In this blog post, we’ve covered the basics of RTD sensors, their working principle, and their benefits. You can choose to utilize RTD sensors according to your specific needs.

So, you too can capture the heat with RTD sensors!

Our Face Book Page Our You Tube Channel Home Page