Introduction:

As we all know, one of the best and most accurate ways to measure temperature is with a Resistance Temperature Detector.

Resistance Temperature Detectors are widely used in temperature measurement applications.

Temperature measurement plays an important role in a variety of industries, including manufacturing, power generation, food processing, scientific research, HVAC, and many more.

In this blog, we will explore these questions and more.

What are resistance temperature detectors? What is their working principle? What benefits do they offer? What are they used for? And why do we think they are the best solution for accurate temperature sensing?

**What is an RTD temperature sensor ?**

As the name suggest, this sensor detects temperature and provides its output in Resistance.

These are the sensors that are designed to detect changes in the electrical resistance of particular materials in response to temperature variations.

They are typically designed and manufactured from materials with an established and repeatable resistance-temperature relationship, thus allowing for accurate temperature measurements over a wide temperature range.

**How Resistance Temperature detectors Work:

The Science Behind Accurate Temperature Sensing–

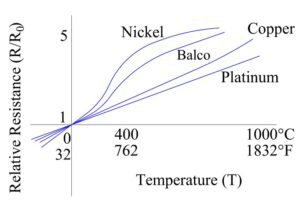

RTDs are usually made with metals like platinum, nickel, and copper because they all have the some resistance-temperature properties. Platinum (Pt) is the most popular RTD element, and it’s made with Pt100, which means it has a resistance of 100 ohms at a temperature of 0 degrees Celsius. When the temperature changes with the RTD element, the electrical resistance changes too, so you can measure the temperature accurately with resistance measurements.

You need to measure the resistance using multimeters, and you can calculate the temperature using formula.

**Advantages of Resistance temperature detectors :**

1. **High Accuracy and Stability:**

They are renowned for their remarkable precision and long-term reliability. The linear correlation between resistance and temperature and the presence of well-defined temperature factors guarantee consistent and reliable measurements.

2. **Wide Temperature Range:**

These are capable of operating over a wide range of temperatures, making them ideal for both cryogenic and high temperature applications.

3. **Excellent Linearity:**

The linear response of these temperature sensors facilitates the calibration and transformation of resistance data into temperature data.

4. **Minimal Self-Heating:**

The self-heating properties of these sensors are generally low, meaning that they do not significantly affect the measured temperature.

5. **Long Lifespan:**

The structural integrity, and stability of these sensors result in a longer service life than many other types of temperature sensors.

**Applications:**

1. **Industrial Processes:**

These temperature sensors are used a lot in industries like chemical production, oil and gas production, and manufacturing where exact temperature control is important for quality and safety.

2. **Aerospace and Automotive:**

They are really important in aeronautics and cars,

where you need to be able to measure the temperature accurately to make sure your engine is running properly,

and, your materials are tested properly.

3. **Environmental Monitoring:**

They are used in places like weather stations, environmental studies, and climate research to keep track of temperature changes in different parts of the world.

4. **Medical and Pharmaceutical:**

These sensors are utilized in the medical and pharmaceutical sectors to ensure precise temperature conditions for the storage, transport, and testing of sensitive materials.

**Conclusion:**

Resistance Temperature Detectors are a great example of precision and reliability when it comes to temperature sensing.

They measure temperatures accurately and reliably, and they have a wide range of temperatures and different uses. This makes them a must-have in industries where temperature regulation and monitoring are important.

As technology improves, these sensors are becoming more and more important in improving product quality, streamlining processes, and advancing scientific research, making them the ultimate temperature sensors.

Our You Tube Channel Our Face Book Page Home